1. The Importance of Glue Level Monitoring in Corrugated Box Production

Corrugated cardboard is one of the most widely used materials in the modern packaging industry. Its structure is formed by bonding multiple paper layers together using adhesive — a key factor that ensures strength, stability, and product quality.

In production lines, glue is stored in dedicated tanks. However, this medium often has high viscosity, adhesive properties, and is prone to hardening if not properly stirred or monitored.

Accurate glue level measurement in these tanks is crucial to:

-

Maintain continuous production

-

Prevent overflow or shortages

-

Ensure consistent adhesive quality

2. Challenges in Measuring Glue Levels

In paper and packaging factories, glue storage tanks pose several measurement challenges:

-

High viscosity causes material buildup on tank walls and sensor surfaces.

-

Agitator movement interferes with conventional level sensing methods.

-

Overfilling or shortage risks if levels are not accurately detected.

-

Low-maintenance operation requirements for 24/7 production environments.

To address these issues, UWT Germany – a world leader in level measurement technology – developed a combined continuous and point level monitoring solution, providing high accuracy and long-term reliability.

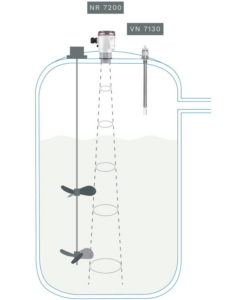

3. The Solution: NivoRadar NR7200 & Vibranivo VN7130

3.1. Continuous Level Measurement with NivoRadar NR7200

The NivoRadar NR7200 is a non-contact radar sensor utilizing 80 GHz FMCW technology, designed for reliable measurement of viscous materials inside tanks equipped with agitators.

Key Features:

-

Narrow 8° beam angle, ideal for slim glue tanks with moving paddles

-

Measuring range up to 20 meters with high-speed signal response

-

Easy configuration via UWT LevelApp, including agitator interference filtering

-

Non-contact design ensures long lifespan and no material buildup

-

WHG certification for enhanced safety and quality assurance

The NR7200 offers continuous, maintenance-free monitoring of glue levels, ensuring smooth and accurate process control.

3.2. Point Level Detection with Vibranivo VN7130

The Vibranivo VN7130 is a vibration-based point level sensor used to detect full and empty levels in glue tanks.

Main Advantages:

-

Accurately detects sticky and viscous materials such as glue and paste

-

Immune to flow, vibration, and air bubble interference

-

Extended tube up to 4 meters, flexible installation

-

Handles temperatures up to 150°C, suitable for demanding environments

-

Supports IO-Link communication for quick setup and system integration

By combining NivoRadar NR7200 (continuous measurement) and Vibranivo VN7130 (point detection), UWT provides a complete and reliable solution for glue tank level monitoring in industrial applications.

4. Benefits of the UWT Level Measurement Solution

-

Accurate continuous and point level measurement in glue tanks

-

Low maintenance, resistant to sticky and viscous materials

-

Prevents overflow and shortages, ensuring stable production

-

Easy system integration via analog or IO-Link communication

-

German technology – reliability and precision from UWT, a trusted global brand

Conclusion

The combination of NivoRadar NR7200 and Vibranivo VN7130 provides an optimal level measurement solution for paper, packaging, and corrugated board manufacturing plants.

With intelligent design, advanced technology, and long-lasting performance, the system enables businesses to better control production processes, reduce operational costs, and enhance product quality.

VNTECH GROUP – Authorized Distributor of UWT Level Sensors in Vietnam

VNTECH GROUP supplies UWT level measurement devices including NivoRadar NR7200 and Vibranivo VN7130, suitable for a wide range of industrial applications.

All products meet European accuracy and safety standards, and come with a warranty of up to 5 years, ensuring long-term reliability and customer confidence.

Guided by our mission to deliver only the best products and solutions, VNTECH GROUP is committed to understanding customer needs, providing installation support, and offering the most efficient and cost-effective solutions — making us the trusted partner of choice in industrial automation and measurement.

Contact Us

VNTECH GROUP is the exclusive distributor of UWT level measurement products in Vietnam.

Contact us today for professional consultation, technical support, and the most competitive pricing on the market.

At VNTECH GROUP, customer satisfaction is our top priority.

We are dedicated to delivering high-quality products and outstanding service, ensuring the best experience for every client.