In the world of industrial automation, where countless electronic devices operate simultaneously, Electromagnetic Compatibility (EMC) is not just a feature — it is a mandatory requirement to ensure system stability and measurement accuracy.

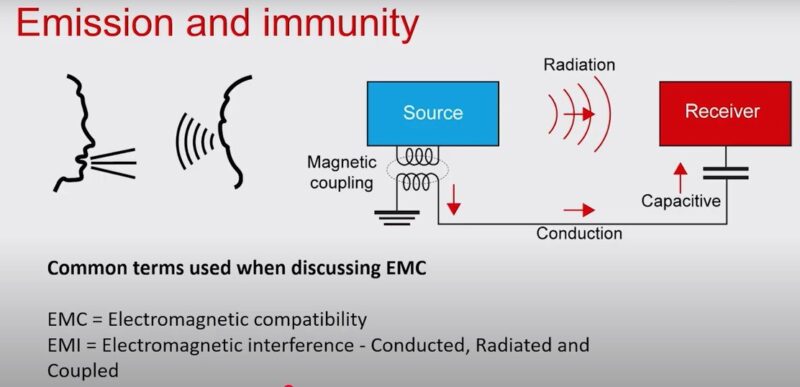

1. Understanding EMC and EMI

-

EMC (Electro Magnetic Compatibility):

The ability of a device to operate reliably in an electromagnetic environment without causing interference to other equipment or being affected by external interference. -

EMI (Electro Magnetic Interference):

The unwanted electrical noise or disturbances emitted by a device, which may occur as conducted, radiated, or coupled interference.

In short:

👉 EMC = resistance to interference

👉 EMI = the source of interference

2. When Equipment Fails EMC Compliance

If a device does not comply with EMC standards, it can lead to:

-

Unstable measurement signals

-

Random electrical surges or abnormal readings

-

Data deviations without an identifiable cause

Such issues may result in production downtime, reduced measurement accuracy, and premature equipment failure — increasing maintenance costs and risks.

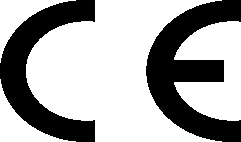

3. CE Marking and the EMC Directive

The CE Mark (Conformité Européenne) is a mandatory certification for electronic products sold in Europe and many international markets.

For electrical and electronic equipment, the EMC Directive (2014/30/EU) ensures that devices:

-

Do not emit excessive electromagnetic interference

-

Are immune to a reasonable level of external interference

- To affix the CE mark on a device, the manufacturer must comply with at least one of the EU directives related to safety, health, or environmental protection.

- For electrical and electronic equipment, the EMC Directive (Directive 2014/30/EU) is particularly important. In this case, the CE mark signifies that the manufacturer is responsible for ensuring the product complies with EMC requirements. It does not imply that the device has superior measurement accuracy or is less susceptible to interference compared to all other products. It simply confirms that the device meets the minimum requirements for safety and electromagnetic compatibility.

- In addition to the EMC Directive, CE-marked products may also fall under other directives such as 2014/32/EU (Measuring Instruments Directive), 2014/34/EU (ATEX Directive), 2014/35/EU (Low Voltage Directive), 2011/65/EU (RoHS Directive), 2014/53/EU (Radio Equipment Directive), and 2014/68/EU (Pressure Equipment Directive), among others.

- Each EU Directive lists the harmonised standards that must be met. For example, the EMC Directive (2014/30/EU) specifies EN, IEC, and ISO standards, including EN 61326-1:2013 — Electrical equipment for measurement, control and laboratory use – EMC requirements – Part 1: General requirements, which applies to measurement, control, and laboratory equipment.

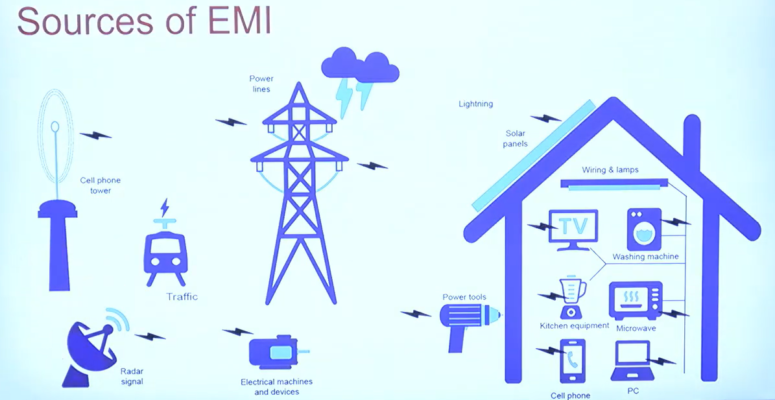

4. Sources and Mechanisms of EMI

Electromagnetic interference can originate from both natural and man-made sources, such as:

-

Lightning strikes, high-voltage lines, and mobile signal towers

-

Electric motors, welding machines, computers, and industrial controllers

The main coupling mechanisms include:

-

Conducted Interference: Through power lines and cables

-

Radiated Interference: Through electromagnetic waves in the air

-

Magnetic Coupling: Induced currents between nearby conductors

-

Capacitive Coupling: Noise transmitted via electric fields between conductors

5. Advanced EMC Standards – DNV and NAMUR NE21

In demanding sectors like marine and process industries, basic EMC compliance is insufficient.

Organizations such as DNV (Det Norske Veritas) and NAMUR (NE21) define more stringent immunity and performance requirements for industrial devices.

Performance criteria typically include:

-

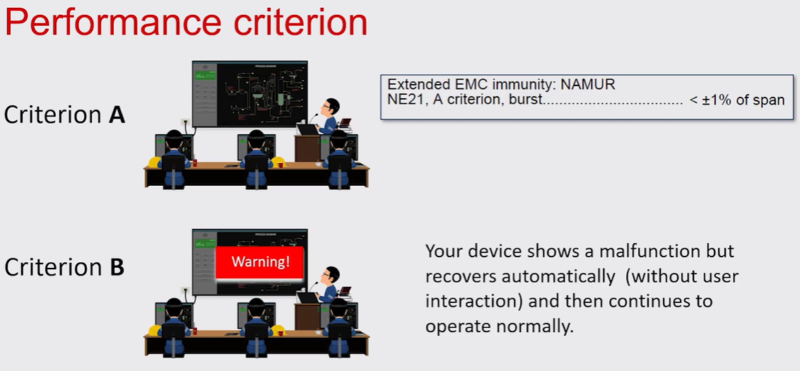

Criterion A: The device operates normally during and after the EMC test.

-

Criterion B: Temporary effects may occur but the device recovers automatically without operator intervention.

Performance Criteria and High EMC Compliance of PR electronics

To evaluate Electromagnetic Immunity (EMS), the tests are classified according to the following performance criteria:

-

Criterion A:

The device must operate normally throughout the entire test period, and any signal deviation must remain within the allowable range (e.g., < ±1% of span). -

Criterion B:

The device may experience temporary malfunctions during testing but must automatically recover without user intervention and resume normal operation.

PR electronics’ Advanced EMC Criteria

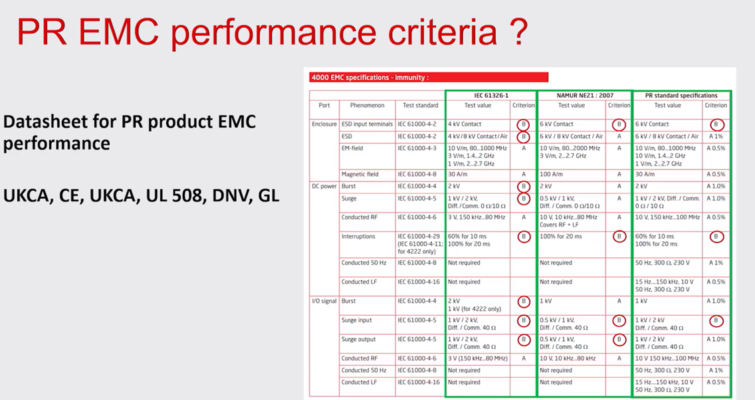

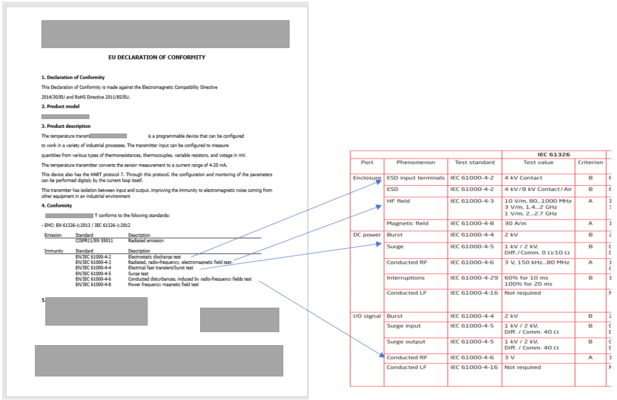

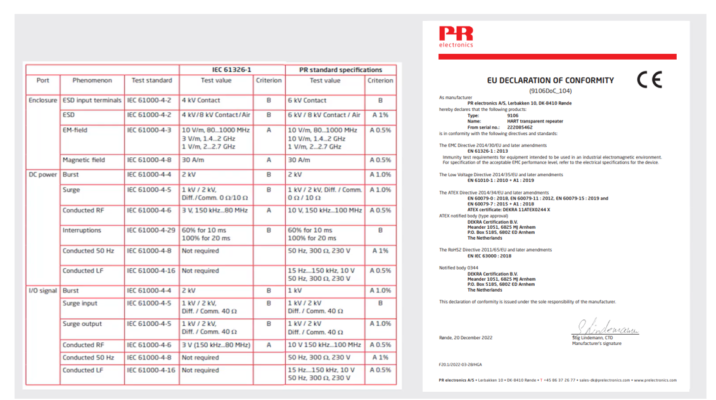

The following technical comparison illustrates three EMC performance levels:

-

IEC 61326-1: Basic standard

-

NAMUR NE21: Stricter industrial standard

-

PR electronics Advanced Standard: Superior to both

To meet these stringent requirements, PR electronics devices undergo a series of highly demanding tests, including:

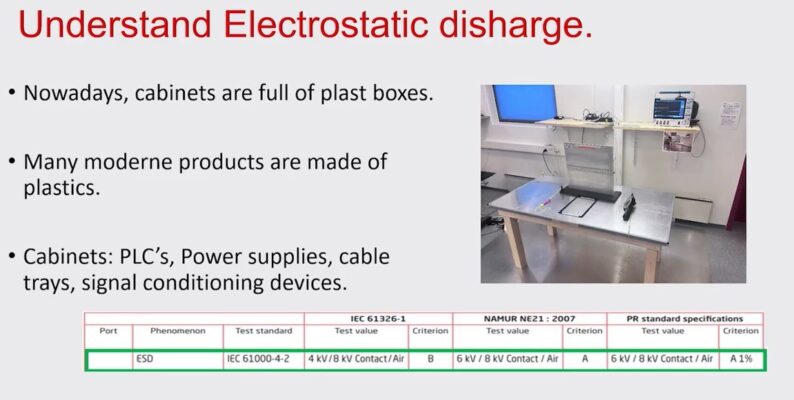

1. ESD Test (Electrostatic Discharge)

Simulates electrostatic discharge when a human or plastic material touches the device — a common occurrence in control cabinets containing plastic enclosures or modern electronic components.

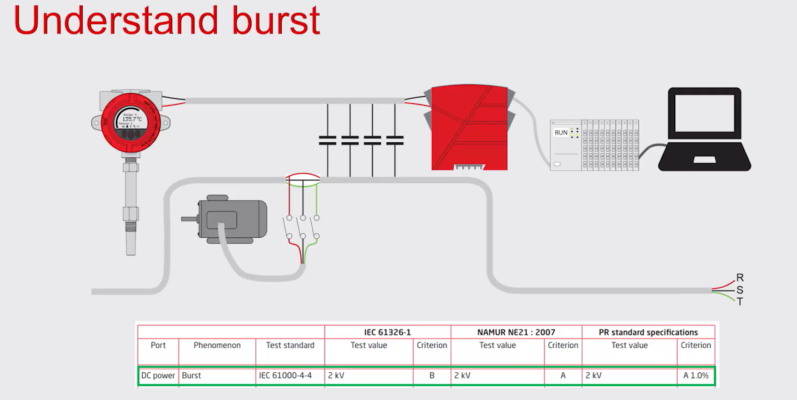

2. Burst Test (Fast Transient Burst)

Simulates high-energy transients generated by switching inductive loads (e.g., motors, relays).

The device must withstand impulse voltages of 1 kV or 2 kV.

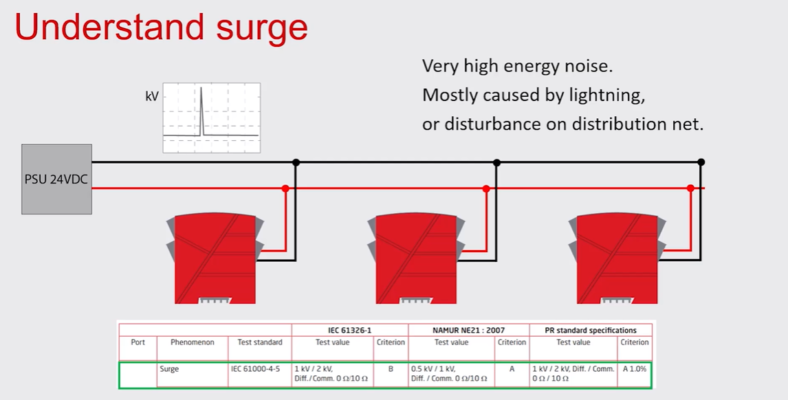

3. Surge Test (Overvoltage or Lightning Surge)

Simulates extreme high-energy disturbances caused by lightning strikes or power line transients on the electrical grid.

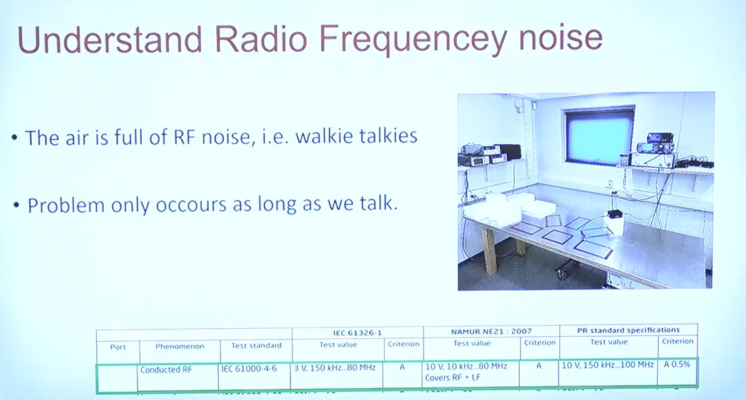

4. RF Test (Radio Frequency Noise)

Verifies stable operation in the presence of radio frequency signals emitted by walkie-talkies or mobile phones.

For example, RF interference often occurs during radio communication.

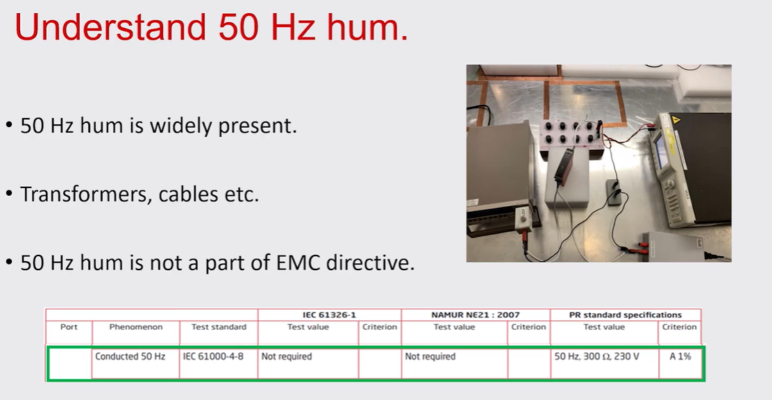

5. 50 Hz Hum Test (Low-Frequency Noise)

Although 50 Hz interference from transformers and cables is not part of the EMC Directive, PR electronics applies its own internal testing standard to ensure the highest performance and noise immunity.

Exceptional Performance of PR electronics

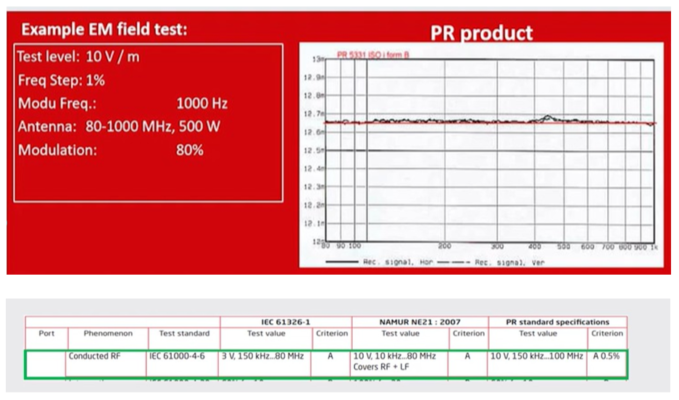

When subjected to strong RF interference at 10 V/m (from 80 MHz to 1000 MHz):

-

The recorded output signal remained nearly flat and stable.

-

PR electronics devices achieved Criterion A, proving outstanding immunity — maintaining accurate measurement data even under strong RF noise conditions.

Certification Documentation

After successfully passing all EMC tests, the manufacturer prepares a Declaration of Conformity to officially confirm compliance with relevant directives, including the EMC Directive.

Why EMC Compliance Matters

In modern industrial environments, EMC and EMI are no longer optional — they are essential factors ensuring safety, accuracy, and equipment longevity.

Products that meet international EMC standards, such as those from PR electronics, enable enterprises to:

✅ Maintain stable and accurate measurement signals

✅ Minimize system risks and downtime

✅ Ensure continuous operation even in high-interference conditions

About PR electronics

PR electronics is a world-leading manufacturer in the field of signal conditioning and industrial measurement.

With over 40 years of experience and a distribution network spanning more than 40 countries, PR delivers advanced, precise, safe, and internationally certified measurement solutions.

About VNTECH GROUP

VNTECH GROUP JSC is the official distributor of PR electronics (Denmark) in Vietnam, providing:

-

Technical consultation

-

Installation support

-

Official warranty and after-sales service

VNTECH GROUP is committed to offering high-quality, CE & EMC-compliant products that meet international industrial standards.

We aim to deliver the best solutions to our customers by understanding their needs, providing on-site support, and optimizing system performance — making VNTECH the trusted partner of leading industrial enterprises.

At VNTECH GROUP, customer satisfaction is our top priority.

We are dedicated to delivering high-quality products and outstanding service, ensuring the best experience for every client.