Differential pressure transmitter for Boiler, also known as boiler differential pressure sensors, differential pressure devices, etc., what are their highlights and applications in the manufacturing industry? VNTECH GROUP will reveal the details below.

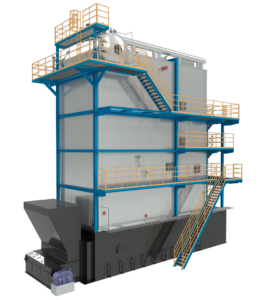

What is an industrial boiler?

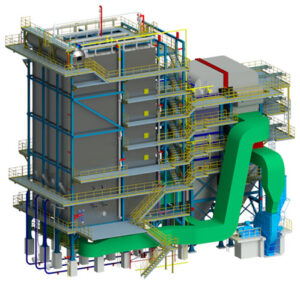

Industrial boilers have an extremely robust design and are carefully operated with the purpose to withstand extreme pressures.

Industrial boilers are often used in factories: Chemicals, Animal feed, Food and beverage,….

There are different types of furnaces and inside is a combination of many different devices to monitor, control and operate the boiler safely, save energy costs, efficiently. These include differential pressure measurement equipment in the application of fluidized bed boilers (FBC boilers) and chain grate boilers.

| Fluidized bed boilers ( FBC boiler ) | Chain grate boiler |

|

|

With the principle of increasing pressure to generate heat, monitoring pressure and temperature is a basic requirement in boilers.

Requirement of Differential pressure transmitter:

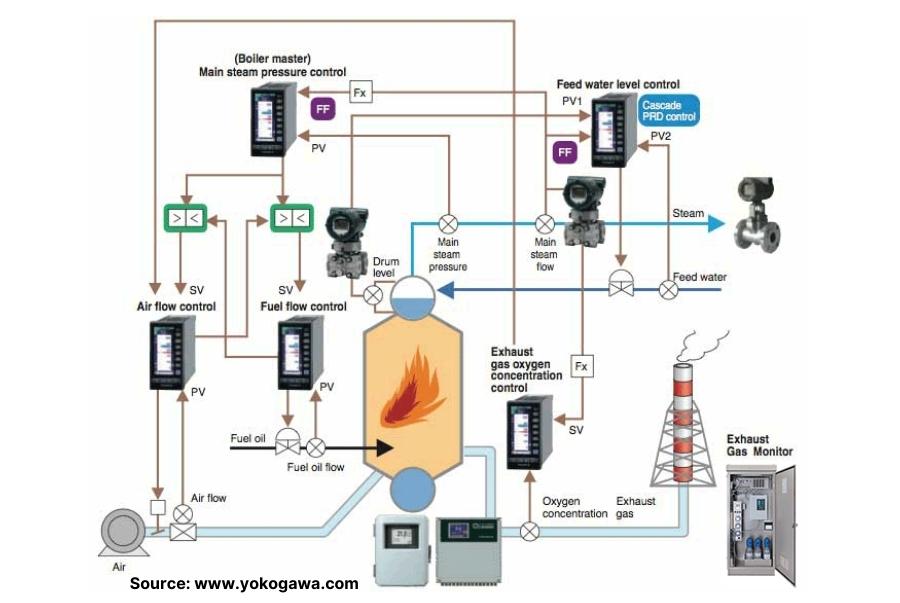

A boiler always has 4 differential pressure monitoring products (differential pressure sensors) which are used sequentially for the following locations:

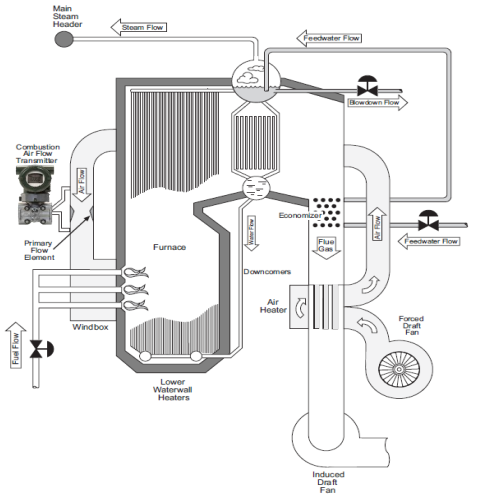

2 differential pressure sensors control combustion chamber exhaust fan ( Boiler Combustion Air Flow )

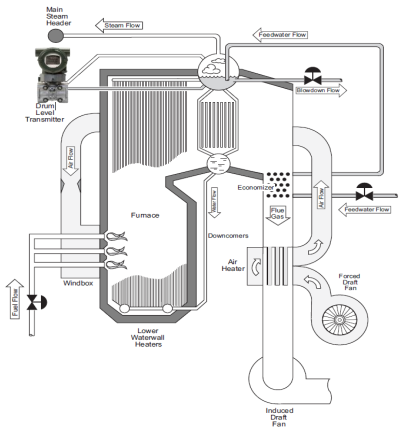

2 differential pressure sensors to control the water level for the boiler ( Boiler Drum Level Measurment )

All at above that is necessary for each boiler. VNTECH GROUP has stocked Yokogawa EJA110E differential pressure sensor from Japan to provide fast and best price in the market to boiler manufacturing customers, factories are Using boilers wishing to replace differential pressure products.

If you have a need to consult products about instrumentation, automation and industrial valves, you can contact us with the information below.