Introduction to an efficient industrial control valve solution

In industrial applications involving water, hot water, compressed air, or saturated steam up to 250°C, selecting a reliable control valve system is critical to ensure stable operation, energy efficiency, and long service life.

The combination of the KFM control globe valve and the Siemens SIPART PS100 smart positioner offers an optimal balance between robust mechanical sealing and advanced digital control technology.

This solution is widely recognized as a cost-effective and high-performance flow control system for modern industrial plants.

Advantages of the KFM Control Globe Valve

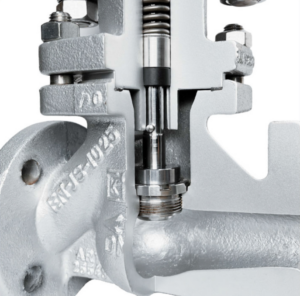

PTFE V-ring sealing for superior tightness and flexibility

The KFM globe valve is designed with a PTFE V-ring sealing system, providing excellent tightness and smooth valve stem movement.

-

Reduced friction on the valve stem

-

Extended service life of both the actuator and the positioner

-

Improved mechanical reliability under continuous operation

Thanks to the elastic properties of PTFE, the valve ensures smooth and precise flow control, achieving:

-

Positioning ratio: 50:1

-

Leakage rate: < 0.01% of Kvs, supporting maximum energy efficiency

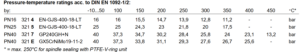

Wide operating temperature range

The KFM control valve operates reliably in temperatures ranging from -10°C to 250°C, making it suitable for a wide variety of industries, including:

-

Food & Beverage (F&B)

-

Textile and dyeing

-

Water and wastewater treatment

Siemens SIPART PS100 – Smart valve positioner for high precision

To fully utilize the performance of the KFM control valve, the Siemens SIPART PS100 positioner delivers advanced automation and diagnostic capabilities.

Automatic commissioning and easy setup

The SIPART PS100 automatically detects the valve stroke and optimizes control parameters with a single button press, eliminating human errors associated with manual configuration.

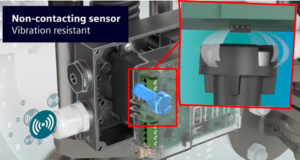

Non-contact position sensing

Using non-contact position sensors, the PS100 avoids mechanical wear and remains unaffected by pipeline vibration, ensuring:

-

Highly accurate position feedback

-

Stable and repeatable control performance

Intelligent diagnostics according to NAMUR NE107

The positioner continuously monitors sealing conditions and supply air pressure.

Early warnings are generated in case of leakage or valve sticking, enabling predictive maintenance and reducing unplanned downtime.

Pre-configured control applications

With built-in application profiles, the SIPART PS100 simplifies operation and automatically adapts to specific control requirements, improving overall system efficiency.

Why is the KFM + SIPART PS100 solution a breakthrough?

Extremely low compressed air consumption

The SIPART PS100 is designed for maximum energy efficiency:

-

Static air leakage: < 6 × 10⁻⁴ Nm³/h

-

Controlled operating consumption: < 3.6 × 10⁻² Nm³/h

-

Maximum air consumption: 0.01 Nm³/h

This significantly reduces operating costs and relieves the load on compressed air systems.

Compact design and easy installation

The compact and modern design of the KFM valve combined with PS100 allows installation in tight plant spaces while maintaining high performance and a clean layout.

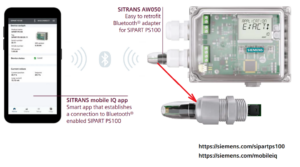

Bluetooth connectivity for convenient configuration (optional)

With optional Bluetooth functionality, engineers can configure and monitor valve parameters directly via smartphone using the SITRANS mobile IQ app, especially useful for valves installed in hard-to-access locations.

Applications of the KFM control valve with SIPART PS100

This integrated control valve solution is ideal for:

-

Water and hot water control systems

-

Compressed air distribution

-

Saturated steam control up to 250°C

-

Food & Beverage processing plants

-

Textile and dyeing industries

-

Water and wastewater treatment facilities

Conclusion

The combination of the KFM control globe valve and Siemens SIPART PS100 represents a high-precision, durable, and energy-efficient flow control solution for industrial applications.

With excellent sealing performance, intelligent diagnostics, low air consumption, and advanced automation features, this system meets the demanding requirements of modern process control.

VN Tech Group JSC is a trusted supplier of industrial valves, instrumentation, and automation solutions in Vietnam, delivering European-standard products and professional technical support.