The granulation drying process is a commonly used method in the production of NPK fertilizer, DAP fertilizer, etc. Below are the key steps in this process:

- Raw Material Preparation: Mixing key ingredients main components such as Ammonia (NH₃), Phosphoric Acid (H₃PO₄), Potassium (KCl), Urea (CO(NH₂)₂), and Limestone (CaCO₃) in the desired ratio to create the appropriate fertilizer formulation (e.g., NPK 16-16-8, 20-10-10).

- Preliminary Granulation: The mixed materials are fed into a Drum Granulator, where they form small granules with initial compression and size.

- Granule Drying: The freshly formed fertilizer granules contain high moisture content (15-20%). A Rotary Dryer is used to reduce the moisture content below 5%, ensuring the required hardness and stability.

- Cooling and Classification: The granules are cooled and screened to classify them according to standard size requirements.

- Packaging: The qualified fertilizer granules are packaged for storage and transportation.

This process ensures uniform fertilizer quality, meeting nutritional and size standards.

Below is a compiled list of all the essential measurement equipment commonly used in the granulation drying production line. These instruments help control product quality, optimize operational processes, and save energy:

1.Temperature Measurement Equipment

- Temperature Sensors (RTD, Thermocouple): Monitor temperature inside the dryer.

- PID Temperature Controller: Automatically regulates the drying temperature.

2.Air humidity and Product Moisture Measurement Equipment

Air humidity Sensor: Measures the supply air to dryer.

Near-Infrared (NIR) Moisture Analyzer: Provides rapid, non-contact moisture measurement.

3. Pressure Measurement Equipment

Pressure Sensors and Pressure Gauges: to monitor pressure in the dryer, compressed air system, and exhaust fan.

4. Flow Measurement Equipment

Gas flowmeter: Measures the flow rate and totalizer of hot gas entering the drying chamber, compressed air, LPG/CNG, steam.

Liquid flowmeter: to measure the flow rate and totalizer of water, liquid-form materials (for dosing or controlling).

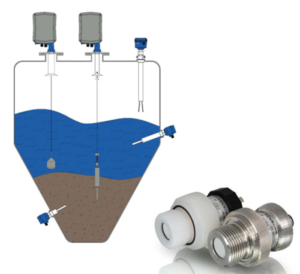

5. Level Measurement Equipment

- Continuous Level Sensor: to monitor material levels in silos and mixing tanks.

- High/Low Level Sensor: to alarm when the material is reaching empty or full level.

6. Rotational Speed Measurement Equipment

Rotational Speed Sensor: to monitor the speed of the dryer.

7 .pH Measurement Equipment

Online pH Sensor: to measure the pH of raw materials or mixing solutions.

8. Oxygen and Emission Measurement Equipment

- O₂ Concentration Sensor: to monitor oxygen levels in the flue gas, to check and adjust for optimizing furnace efficient.

- Concentration of Emission Gas Analyzer (CO, CO₂, NOx, SOx): to track the exhaust gases to environment.

9. Vibration Measurement Equipment

Vibration Sensor: Monitors the operational condition of machinery

10. Weight Measurement Equipment (Belt Scale)

- Dynamic Belt Scale: Measures the mass of materials passing through the conveyor.

- Load Cell: Measures the weight of materials in silos or storage tanks.

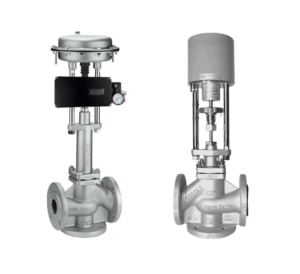

11. Pneumatic or Electrically Actuated Linear Control Globe Valve

- Controls the flow of hot gas or steam in the dryer.

12. Data Logger

- Used to collect, store, and monitor data from measurement sensors in the industrial system.

Contact Us:

We are committed to providing optimal solutions for measurement, control, and monitoring, along with professional services to fully meet our customers’ needs.

———————–

VNTECH GROUP – Your Partner for Automation, Instrumentation & Industrial Valves

📞 Hotline: 0918 113 733

📧 Email: info@vntechgroup.com.vn