1. Introduction to the Modern Monitoring Solution

In the era of Industry 4.0, the need for remote oil level monitoring has become essential for businesses operating fuel tanks, chemical storage, or industrial oil systems.

Traditional manual methods — physical checking and handwritten logs — are time-consuming and error-prone.

The monitoring solution powered by IoT (Internet of Things) technology provides an advanced, automated, and accurate way to track tank data in real time, improving efficiency and safety.

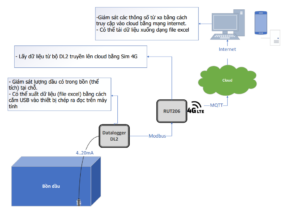

2. System Components and Operating Principle

A complete intelligent monitoring system consists of three key components:

1️⃣ Hydrostatic oil level sensor LMP307

2️⃣ Data logger DL2

3️⃣ IoT Gateway RUT206 for cloud data transmission.

Hydrostatic Oil Level Sensor – LMP307

-

Industrial-grade output signal 4–20mA, minimizing interference and ensuring high accuracy.

-

Measures both oil level and volume precisely, suitable for harsh environments.

Data Logger DL2

-

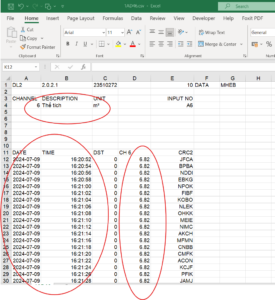

Receives signals from the sensor and records real-time measurements.

-

Stores and allows data export in Excel format via USB for on-site inspection.

-

Provides a historical log of level changes for analysis and reporting.

IoT Gateway RUT206

-

Connects to DL2 using Modbus RTU/TCP protocol.

-

Uses a 4G SIM card to transmit data to the Cloud platform via MQTT.

-

Enables users to access the monitoring dashboard anytime, anywhere via PC or smartphone.

3. Key Benefits of the IoT Monitoring Solution

-

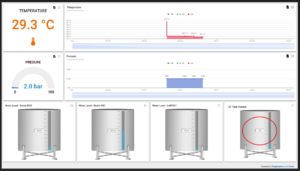

Comprehensive remote monitoring: Real-time data automatically uploaded to the Cloud for continuous tracking.

-

Visualized data display: Graphs and dashboards show oil volume trends over time.

-

Save time and cost: Reduce manual inspection and eliminate human errors.

-

Smart alerts: Instant notifications when oil levels exceed predefined thresholds.

-

Performance analytics: Historical data supports maintenance planning and operational optimization.

4. Practical Applications of the Monitoring Solution

This IoT-based monitoring system is suitable for:

-

Fuel stations and industrial oil depots

-

Chemical, water treatment, and food processing plants

-

Vehicle fleets and machinery using industrial oil

-

Automated tank management systems across multiple sites

No matter the scale, this IoT monitoring solution ensures accurate, continuous, and cost-efficient control of liquid storage.

5. Conclusion

Implementing an IoT-based remote oil level monitoring solution is a key step toward digital transformation in industrial operations.

It allows enterprises to monitor in real time, detect issues early, save manpower, and enhance operational efficiency.

If you’re looking for a smart, reliable, and scalable monitoring solution, contact us today for a detailed consultation and live demo.

VNTECH GROUP – Vietnam Measurement Equipment & Industrial Valves JSC is proud to be a comprehensive solutions provider in the fields of measurement, control, and automation for the water and environmental industries.

With trusted global brands such as UWT (Germany), PR Electronics (Denmark), BD Sensors, Suku, TA, and Yokogawa, we are committed to delivering high-quality products and specialized technical services to customers nationwide.

Contact Us

We are the exclusive distributor of this product line in Vietnam.

Please contact us for detailed consultation and to receive the best price and technical support tailored to your needs.

At VNTECH GROUP, customer satisfaction is always our top priority.

We are dedicated to providing our clients with the best quality products and services, ensuring long-term reliability and performance.

📞 Contact us today to discover the optimal monitoring solution for your requirements — with the most competitive pricing on the market.

Xem thêm:

Cảm biến đo mức liên tục 4-20 mA